This is going to be a 2 part post since I have some details that I want to show to help better explain some of the situations we found. I thought I would start out by discussing our material choices and general strategy.

When we bought the house there were finished stud walls in front of the foundation walls and sill with fiberglass batt insulation. When this was done in the 1970s they also added some fiberglass to the sill area. This was done very poorly and irregularly. It also had paper facing on some of it, which is a bad idea unless you are going to define your line of moisture barrier and be consistent. Once we removed the walls and the miscellaneous fiberglass batt insulation we found an earlier layer of mineral wool (aka rockwool) that had been stuffed in between the exterior balloon frame wall studs above the sill. However the sill itself had not been insulated. We also encountered miscellaneous newsprint from 1906. My guess is that the mineral wool is probably a little bit later than the newsprint.

Once we evaluated the situation, we quickly decided that before we could install the new mineral wool we need to seal any air gaps. I will get into all of the conditions tomorrow, but we decided to go with the DOW Great Stuff Big Gap Filler. It is cost effective at $4.79 a can and pretty easy to work with. As you can see we bought quite a bit and ended up going through about 10 cans (the rest will be returned to Home Depot). We used it where the wood sill plate met the foundation and in any gaps around the old mineral wool. Also to fill in the areas that did not have the old mineral wool (i.e. below the bay window).

Before we knew that there was mineral wool already there I had decided to use mineral wool batts already. As I had mentioned before, mineral wool has some advantages for a condition like this, including better fire resistance, better R-value per inch, acoustical properties and it can handle moist conditions better than fiberglass. It is also denser and tends to deter pests more then fiberglass. I have specified mineral wool on lots of occasions (usually for sound isolation between 2 spaces) but I had never worked with it. First I had to find it, which proved more difficult than I thought it would be. In the end I found that our local lumber yard can order it, although it took them a little bit to figure out what exactly I wanted and how the quantities worked. I ended up with Thermafiber 3″ thick batts. Unlike fiberglass they don’t come in a roll because they are more rigid and don’t take to rolling. Instead they are 16″ wide (like a typical fiberglass batt) and 48″ long. The bags we ordered contained about 48 sf and cost around $42.

I was warned that it was more itchy than fiberglass, but we were planning on wearing long sleeves, gloves and masks anyways, so I wasn’t too worried. Once I opened the first bag and did a sample cut I discovered that it cuts more easily and cleanly than fiberglass (I was using a straight edge and an Olfa Knive). Of course our bays are not a standard bay size and are typically around 14″ rather than the 16″. The height we needed was about 9 – 10″. So after a little bit of math and some trial and error in fitting the pieces we determined that we could get five 9 1/2″ x 16″ pieces. These fit nice and snugly in between the joists. We decided to use 2 pieces per bay.

This actually went quite quickly. I did the cutting while Mr. S. installed them. For the front of the house (parallel to the bay) we continued to use the small pieces and just butted them up next to each other. We found the longer pieces were hard to push into place. I also found it was about as itchy as fiberglass, but because it was less messy to cut I actually prefer it by far to work with.

We have already noticed a difference in the basement and on the first floor. We still need to do the rear wall of the house. In that case there is only a narrow gap between the floor joist that runs parallel to the foundation wall and the wall. It is going to probably be a little trial and error.

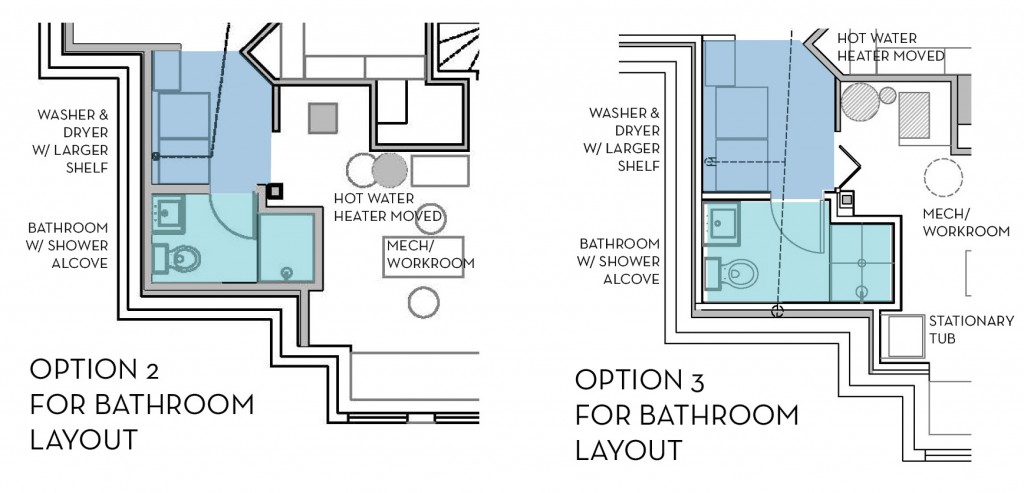

Tomorrow I will show you some sections of the sill condition so I can better explain our strategy.

*For all of our Basement progress click here.